Banana Leaf luncheons are common treats for most in Malaysia. The place I went to was bustling with patrons relishing their experience. This restaurant is famous for its banana leaf luncheons, but that is not what I came for. Without any hesitation, I found myself a spot and ordered a fried instant noodle.

While waiting for my food, I saw the waiter walking up and down, carrying a three-compartment dishes carrier. Customers who ordered the Banana Leaf set can enjoy unlimited replenishment of dishes. I cannot take my eyes off the appetizing dishes.

The waiters were trying their best to serve all customers within a short span of time. However, as the demands of customers kept on increasing, the carriers turned empty quickly, in which case the waiter will have to replenish them from the kitchen.

Figure 1: Example of Three-compartment dishes carrier

“If indeed I intend to make some changes about that, what would I change to make things better?” I thought. I started assessing the surroundings through my Lean lenses.

By observing the operations in the restaurant, push and pull system flashed through my mind. I realized that the Banana Leaf Restaurant implemented both push and pull system. They used push system for the preparation of banana leaf dishes as it requires a longer time to be prepared. However, by not knowing the demand of the customer, this has resulted in food wastes. To avoid preparing extra dishes, they could use Kanban system as replenishment system in which case they can start preparing the dishes only when the dishes reach a minimum level. By doing so, the wastage of dishes can be reduced. For other food and drinks order, they implemented pull system, which is also known as Just in Time. They will only prepare the food whenever they receive the order from customer.

Viewing the conditions scene by scene, I noticed the obvious. One of the main reasons why the waiters are shuttling back is to refill their three-compartment dishes carrier, which becomes empty frequently.

Why not use Two bin Kanban system? Instead of only one three-compartment dishes carrier, an extra carrier set can be dispatched to the immediately available waiter to fulfil additional customer demand as the empty carrier gets replenished by kitchen staff. Besides that, the use of a trolley cart to place and move all the three-compartment dishes carrier is more ergonomic. It could lower the physical burden of the waiter and ensures the safety of customers who are walking around.

Figure 2: Trolley cart for food

“Why is my order taking so long?”, I said to myself as I heard growling sound from my stomach.

I shifted my sight to the cooking area. There is only one cook with a wok. After the completion of an order, the cook has to clean his wok before proceeding to the next order. This is where quick changeover, which is also known as Single Minute Exchange of Die (SMED) can be applied to reduce the time taken for the cook to prepare for the next order after completing one. There are several activities that can be listed down as external activities, such as prepare water and brush for washing as well as prepare oil and ingredients for the next order. By doing so, the cook will be able to prepare for the next order without a long delay.

All of a sudden, a waiter interrupted my track of thoughts.

“Moi, Maggie goreng telur mata kerbau.”

He served me fried instant noodles with a sunny-side-up egg. This was definitely not mine as the egg is certainly my least favourite. I raised my hand to get his attention to no avail. How I wish there was an Andon system here! It would be much easier if they were to be notified immediately when customers need assistance. Nowadays, the Andon system is being widely used mainly in the bubble tea shop or ambient coffee house as a convenient notification system.

Figure 3: Waiter calling button widely used in coffee house

Right after I managed to inform the waiter, I saw him murmuring with his colleague. Due to the absence of numbers or indicators on each table, they have to communicate by pointing at the tables. To have numbers or indicators on the table is a real simple act, but it is useful to prevent waiters from serving the wrong table. Besides, having numbers or indicators as visual management is capable of boosting the efficiency of waiters. Some people misunderstood visual management as a technique for housekeeping. Visual management does not only shine the working environment; it also helps to bring up all wastes (Muda) that might be affecting the performance of the waiters.

Figure 4: Number plate can be used for visual management

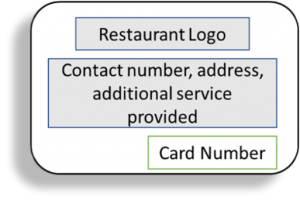

However, there is a Poka-Yoke they did. The moment they served; they will put a small card with number on it for customers to bring it to the cashier for payment. This effortless act helps them to prevent from making a mistake during customer payment. Moreover, there is a contact number and additional services which they provide listed down in the card; it is certainly a good way to promote their additional services.

Figure 5: Draft of card with number / indicator

After enjoying my food, I brought the small card and walked to the cashier. As the restaurant is not spacious, there were several times where the waiter nearly spilled all the dishes to avoid bumping into me.

“Why would they arrange the tables and cashier this way?”, I wondered.

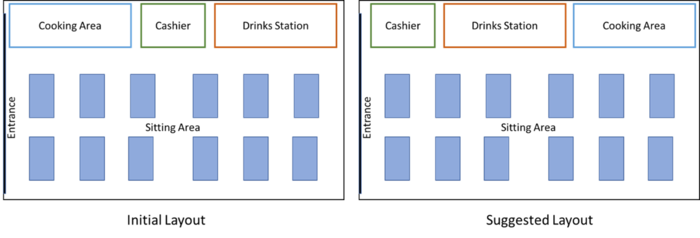

This is definitely not a value-added flow. The cashier was placed between the cooking area and drinks station. First of all, the waiter would need to walk to the drinks station then to the cooking area after receiving an order from the customer. Then he will have to go to the cashier to collect the small card for payment purpose. Most importantly, it is unsafe for customers to walk to or queue up at the cashier, especially when the waiter is carrying hot cooked food or hot drinks. A value-added flow should be seamless, non-redundant and non-disruptive. The restaurant should reorganize to increase the efficiency of the waiter. The cashier should be placed at the entrance for ease of customers. Moreover, the waiter will face less impedance inflow while delivering customer orders as the farthest distance to travel will be shorter. With the cashier segment relocated closer to the entrance, customers will be able to queue orderly without severely restricting the communication between the cooking area and the drinks station.

Figure 6: Initial and Suggested Layout of Banana Leaf Restaurant

After all, they served nice food and the price is worthy.

Lean approach has introduced widely approximately during the 1980s; most of the people think that Lean will only work in manufacturing industries. However, in the 2000s, due to competitive markets, business providers started to implement Lean in various service sectors. Business providers increasingly faced the need to reduce cost while at the same time, necessitated the sustenance of customers’ satisfaction. Thus, I would say the Lean Approach is one of the most convenient techniques that can be instantly applied for a quick improvement, as in the words of one of its proponents, Shigeo Shingo: to make things easier, faster, better and cheaper. As for how it can also be observed, most of Lean concepts are tricks and hacks in our daily life, which does not need huge investment in time nor money.

Ready to improve your workplace by implementing lean but no idea where to kick start? Check out our website https://lss-academy.com/ to get connected with us.