We can’t solve problems by using the same kind of thinking we used when we created them. The diagram below can be used to explain DMAIC, together with LSS Academy to strive for a breakthrough performance in business and continual improvement

Productivity

You can increase productivity in your organization through improving your operational processes using Ascent 3E. But most processes are performed by people, so there is a need to work on your people as well. You need the right people with the right skills level and the right mental approach to implement and maintain the process improvements you will achieve through Ascent 3E. Read more….

Framework

The QS E3 Simulation is a key component in the Ascent E3approach and is unique to it. The QS in its name refer to Quality and Speed, which are critical to a peak performance operation. There are two different versions of the simulation, one for manufacturing (QS Invent) and one for services (QS Finance). Read more…

ROI

There have been some interesting new approaches to calculating return on investment (ROI) recently, and we have adapted some of these so you can see not only at the end of a project what is your immediate ROI, but also how this ROI will continue to grow as you continue to use the lean six sigma and peak people performance approaches and that you are in fact getting a ‘bang for your buck’. Read more…

Ascent E3 Solutions

2. Plant Optimization

1. People Performance

3. Process Improvements

4. Technological Returns

5. Training & Consultancy

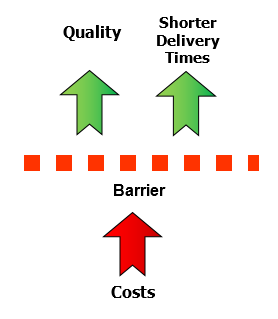

- In the past, companies believed a gain in one performance area required a trade off in one or more of the other dimensions.

- For example, to decrease delivery time firms hired more expeditors, which drove up costs, while product quality suffered in the rush to get product out the door.

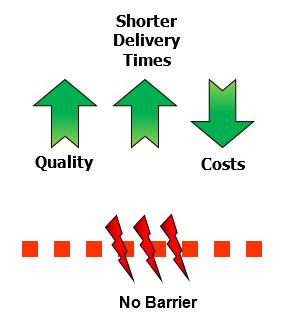

- The new paradigm says a performance gain in one area requires or will result in performance gains in the other dimensions.

- For example, achieving a sustainable decrease in delivery time requires that rework, scrap, and other inefficiencies be eliminated in the production process, resulting in higher product quality and lower production costs.

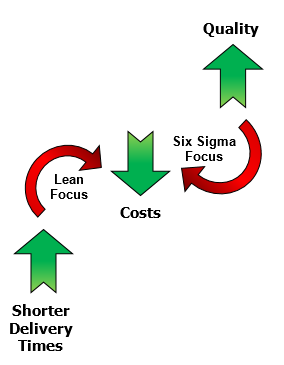

- To implement the new paradigm, companies turned towards rapid process improvement strategies – Lean Six Sigma Workshop – Workouts.

- Tools: Lean focuses on reduced lead time and reduced costs.

- Tools: Six Sigma focuses on improved quality and reduced costs